LDM printers

FDM stands for liquid deposition modeling and refers to 3D-printing with semi-viscous to viscous materials such as clay or food pastes.

Safety Rules for Lutum 4 Clay Printer

- Keep the work area clean and free of any debris or obstacles, which can cause accidents or affect the performance of the printer.

- Only use clay that is compatible with the printer (low levels of grog), and follow the instructions for loading and unloading the clay.

- Check the air pressure gauge and ensure that the pressure does not exceed the recommended limit of 4 bars. Never attempt to increase the pressure beyond the recommended limit.

- Never touch the printer's moving parts or attempt to reach inside the printer while it is in operation. This can cause injury and damage to the printer and you.

- When finished using the Lutum 4 clay printer, turn it off and disconnect the pneumatic tube.

Instructions for Lutum 4 printer

Please only use this printer after talking to Makerspace staff.

- How to use the Lutum Clay Printer at A-huset, LTH (PDF, 16.3 MB, new tab)

- FAQs on VormVrij's Lutum page (scroll down to Support & Answers)

- Instruction videos on Yao van den Heerik's (at VormVrij's) YouTube channel

Slicer profiles

Manual slicer setup

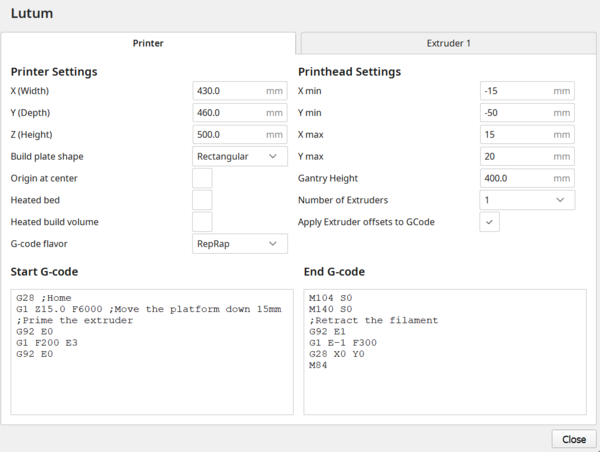

More printer profiles to come, but can also be set up manually by defining size of build plate (430 mm x 460 mm x 500 mm), gcode flavour RepRap (instead of Marlin) and start and end gcode.

Start gcode

G28 ;Home

G1 Z15.0 F6000 ;Move the printhead up 15mm

;Prime the extruder

G92 E0

G1 F200 E3

G92 E0

End gcode

M104 S0

M140 S0

;Retract the filament

G92 E1

G1 E-1 F300

G28 X0 Y0

M84

Cura screenshot